Wirtgen

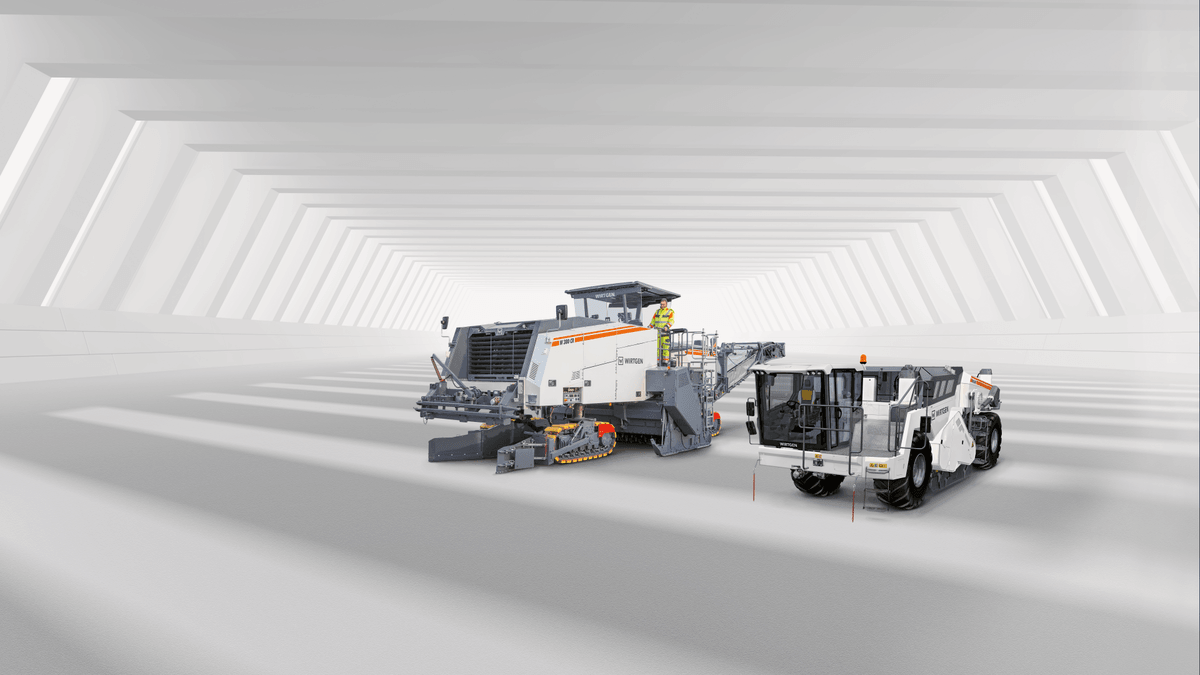

Cold milling machines

Asphalt and concrete pavements can be cost-effectively removed with cold milling machines. The range of applications extends from the complete removal of asphalt and concrete to the layer-by-layer removal and levelling of asphalt and concrete surfaces. With WIRTGEN cold milling machines, it is possible to machine working widths from 35 cm up to 4.40 m and working depths up to 35 cm in a single pass. In addition, a large number of different milling drums, such as ECO cutters or fine milling drums, ensure that machines can be used with a high degree of flexibility.

Recyclers and soil stabilisers

Cold recyclers are used to prepare asphalt pavement on site. In this process, the existing pavement is granulated with the milling and mixing rotor and prepared by adding precise amounts of bituminous binding agents, cement and water. The result is a homogeneous material that can be used to directly repave the soil. Soil stabilisers use the milling and mixing rotor to mix pre-spread binding agents such as lime or cement into the existing, less stable soil and transform it into a high-quality material directly on site.

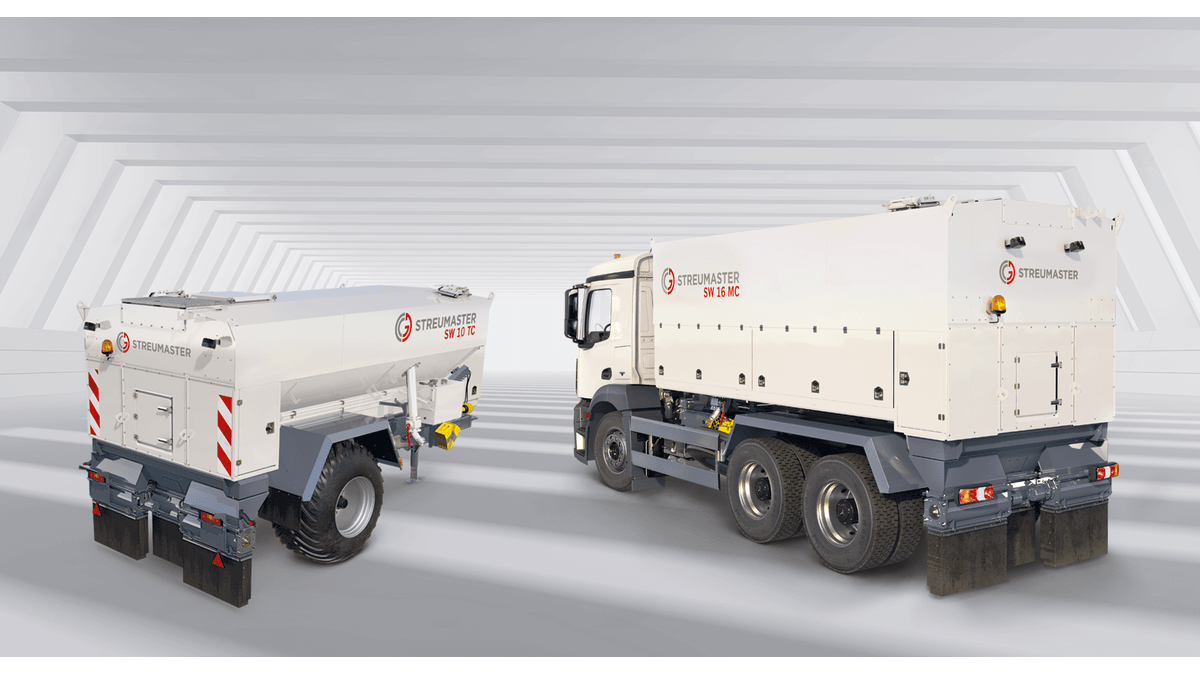

Binding agent spreaders

Spreading large quantities of binding agents while adhering to the specified accuracy at the same time is of paramount importance in both soil stabilisation and cold recycling. The sophisticated binding agent spreaders from Streumaster meet these requirements with superior ease. In addition, our comprehensive product portfolio takes due account of both different performance requirements and the availability of tractor vehicles. The binding agent spreaders from Streumaster are therefore on offer in various model designs: as attachment units, trailers, built-up units for mounting on a carrier vehicle, or self-propelled spreading machines.